Tool holders for lathe are a kind of fixture device used to install tools, which are used to clamp the tools and fix them on the machine tool. As an important “bridge” connecting the machine tool and the tool, the tool holder is related to the processing accuracy, tool life, processing efficiency, etc., and ultimately affects the processing quality and processing cost.

BT tool holders

BT tool holders have the characteristics of strong grip, good rigidity, and wide applicability. The models range from 30 to 100, with BT40 being the most commonly used model. BT tool holders are suitable for machining processes such as milling and drilling.

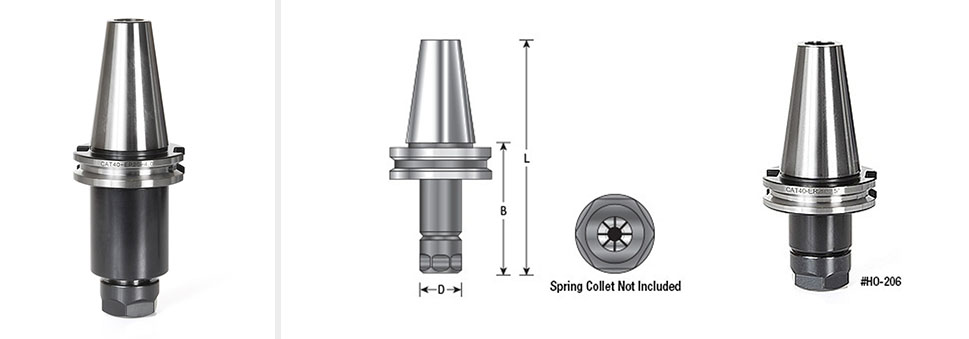

CAT tool holders

CAT tool holders are characterized by compact structure, good rigidity, light weight, etc. CAT tool holders range from 30 to 50 models, among which CAT40 is the most commonly used model. CAT tool holders are suitable for processes such as drilling and milling.

HSK tool holders

HSK tool holders have the advantages of high precision, high speed, high rigidity, etc., and are suitable for high-speed machining and high-precision machining. HSK tool holders range from 32 to 100, among which HSK63 and HSK100 are the most commonly used models. HSK tool holders are suitable for high-speed milling, cutting, drilling and other processes in CNC machining.

Your Attractive Heading

Turning tool holders have the characteristics of strong rigidity, high precision, stable clamping, and easy tool replacement. They are usually used to fix turning tools. Turning tool holders are widely used in turning processes, suitable for various scenarios from roughing to finishing, and can meet the turning processing needs of various materials.

Drill chucks

Drill chucks are tools used to clamp drill bits. They are widely used in lathes and drilling machines due to their flexible clamping range, automatic adjustment of the center position, manual or automatic clamping, high precision, and high durability. They are suitable for various turning, drilling, and multi-process compound processing operations.