Precision Stamping Parts

Precision stamping parts have better quality, Metal stamping dies have complex structures, high manufacturing precision requirements, and the product surface is plasticized by fixed molds. Precision stamping parts have stronger applicability and can be processed into parts of any shape and size according to production requirements to meet the needs of different industries.

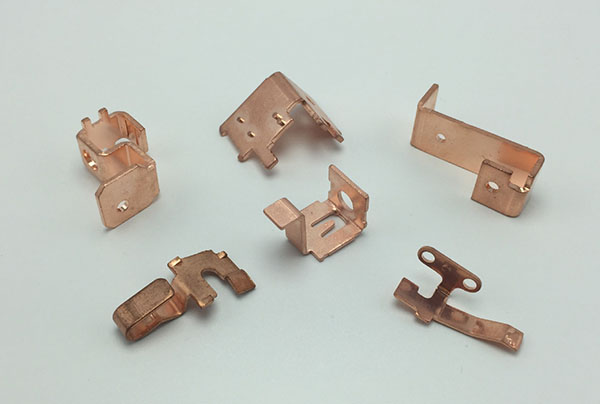

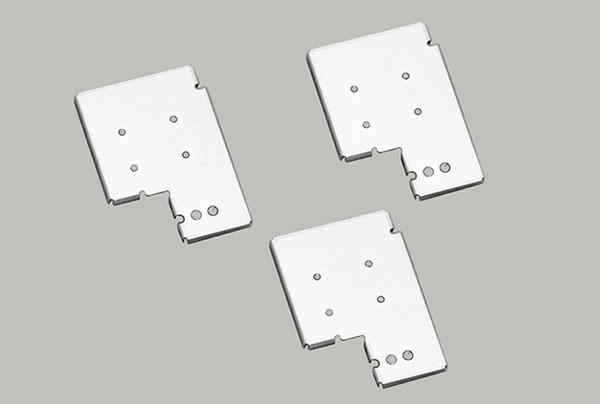

Custom Precision Stamped Parts

Precision stamping parts are parts that are formed by using stamping technology to process plates, strips, pipes, etc. through special equipment. Precision stamping is achieved by improving the guiding accuracy of the punch and the mold, reducing the matching clearance of the male and female molds, increasing the reverse ejection pressure and the V-ring pressure ring pressure and other process measures. It is suitable for mass production and is widely used in electronics, automobiles, aerospace and other industries.

Precision stamping parts have good quality, high precision, small size and other advantages. Precision stamping technology has been widely used and developed. Chaoyue Machinery targets precision parts with strict requirements such as small, high precision and complex structure. It not only ensures the consistency of shape, dimensional accuracy and position accuracy of precision stamping parts, but also improves the response speed to customers, improves the production efficiency of products and shortens the delivery time.

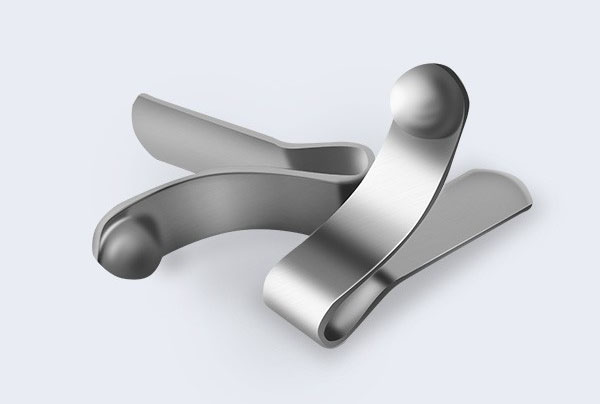

The precision parts we customize include Electromechanical Components ( Battery contacts, terminal connectors, EMI/RFI shielded enclosures), Automotive Systems ( Door panel assemblies, hood reinforcements, chassis structural frames, suspension components), Appliance Engineering (Die-cast housing assemblies, reinforced door frames, load-bearing brackets), Medical Device Fabrication (Surgical-grade clamps, disposable syringe bodies, orthopedic implants), Opto-Mechanical Systems (Aspherical lens elements, precision lens barrels, adjustable optical mounts). For more CNC machining, stamping and molding solutions, please contact us.

Advantages of precision stamping technology

High precision

Precision metal stamping parts are characterized by high precision. Through advanced production equipment and strict quality control, the dimensional accuracy of precision metal stamping parts can reach the micron level, and they are used in various high-demand application scenarios, such as aerospace, automobile manufacturing and electronic products.

High strength and durability

Precision metal stamping parts are made of high-quality metal materials and processed by precision stamping technology. These parts have excellent tensile strength and wear resistance, and can be used for a long time in harsh working environments, reducing the frequency of replacement and maintenance.

Good surface quality

Precision metal stamping parts use advanced surface treatment technology, and the surface finish and flatness of these parts are very high. It provides convenience for subsequent surface treatment processes (such as electroplating, painting, etc.), and also helps to reduce friction and wear and extend service life.

Customizability

With high-precision machinery and cutting-edge technology, it can easily cope with stamping needs of various shapes, thicknesses and materials. CHOYUE machinery can produce components suitable for different applications, greatly improving the diversity of production and providing you with more choices.

Precision metal stamping parts occupy an important position in the manufacturing industry with their advantages of high precision, high strength, good surface quality and high customizability. If you are looking for a reliable and efficient solution for precision metal stamping parts, please contact us. CHOYUE Machinery must be your best partner.

Production steps of precision metal stamping parts

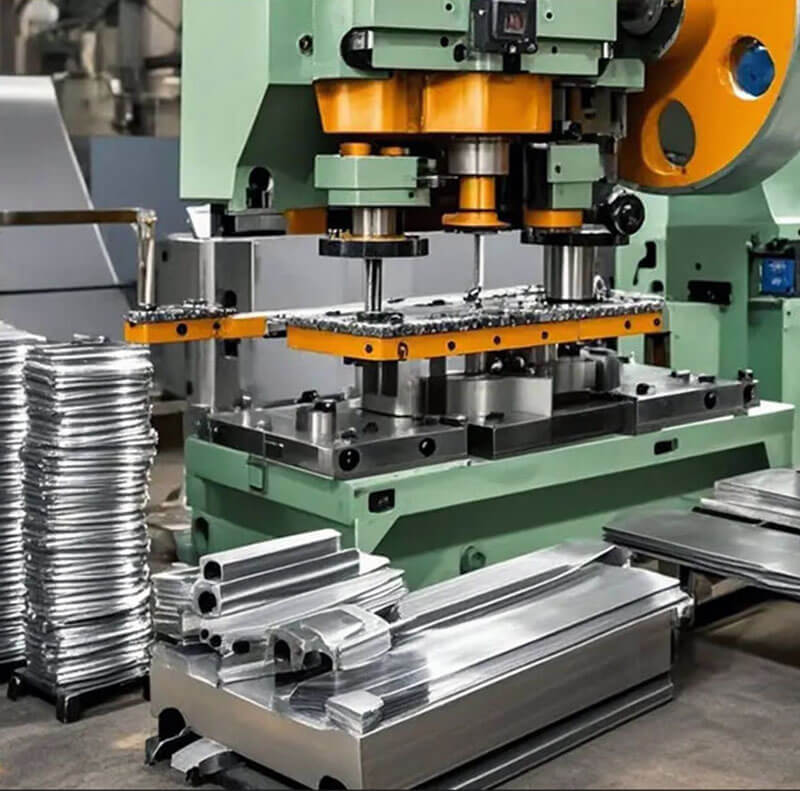

The manufacturing process of precision stamping parts includes stamping, mold manufacturing, material selection, clamping positioning and mold design.

During the stamping process, select appropriate materials according to the requirements of the drawing, perform stamping operations in the mold, and plastically deform the sheet through the pressure and shape of the mold to achieve the shape and size required by the product.

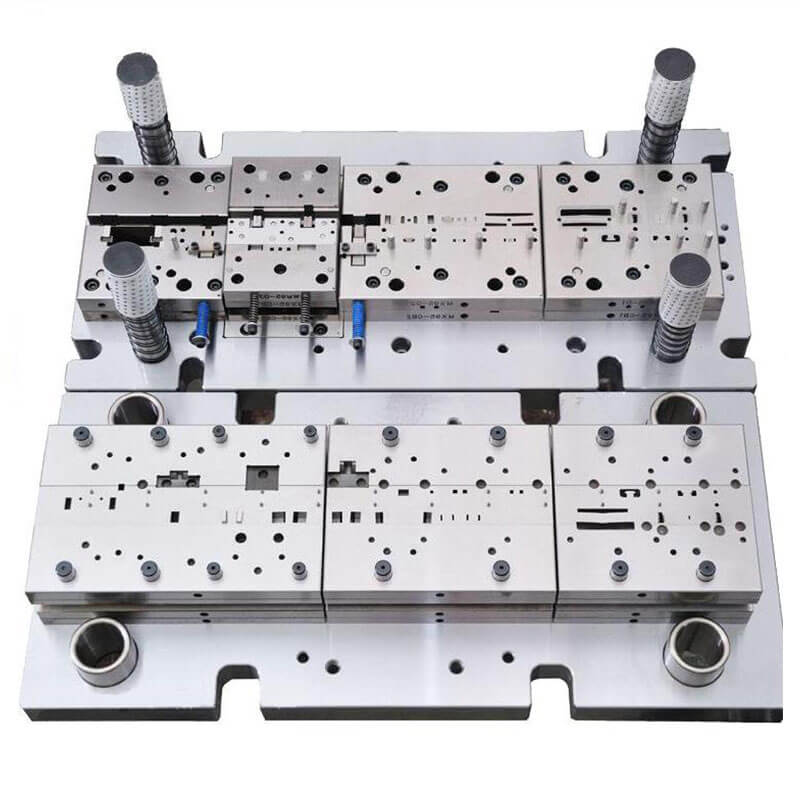

Metal stamping dies is an important part of precision stamping parts manufacturing. The quality of metal stamping dies directly affects the processing accuracy and quality of products. The die is divided into two parts, upper and lower, and is generally made of high-speed steel or cemented carbide.

In terms of material selection, the material of precision stamping parts needs to have high hardness, good ductility, and no internal defects such as pores and inclusions to ensure the quality of the product after processing.

Then, during the stamping process, in order to ensure the shape and size accuracy of the product, clamping positioning must be performed to ensure that the relative position between the mold and the material does not deviate.

When designing a mold, it is necessary to carry out multiple links such as concept design, structural design and process design according to product requirements. The optimal mold can be designed by comprehensively considering the product’s shape, size, precision and possible problems that may arise during the stamping process.

Precision metal stamping supplier

As a true industry leader, we provide personalized and customized precision metal stamping solutions. Please contact us for any needs.

Application of precision stamping technology

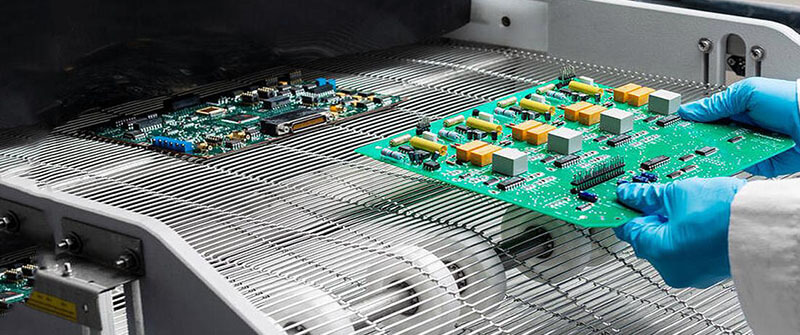

Electronic field

The field of electronic manufacturing has high requirements for the accuracy and precision of parts. These parts require high-precision dimensions and complex shapes. Precision stamping can produce connectors and plug-ins in countless shapes. Precision stamping parts are widely used to manufacture high-precision products such as connecting parts of various electronic components and mobile phone parts.

Automotive field

In the process of automobile manufacturing, precision stamping technology is used to manufacture body parts, lathe parts, chassis parts, etc. It can produce parts with complex shapes and precise dimensions to meet the needs of automobile manufacturing for high-strength and lightweight materials and improve the overall performance of the car.

Aerospace field

From aircraft structural components to engine parts, precision stamping technology provides key support for the aerospace industry. It can produce parts that meet extreme environmental requirements and have extremely high reliability, which is crucial to ensuring flight safety and improving performance.

How to choose the material of precision metal stamping parts?

Precision stamping parts are usually used in high-precision, high-speed and high-load applications, so there are high requirements for the strength, hardness, wear resistance and corrosion resistance of the material. Choosing the right material is essential to ensure product quality, performance and cost-effectiveness.

In summary, the material selection of precision metal stampings should comprehensively consider factors such as strength, hardness, wear resistance, corrosion resistance, processing performance and cost. By comparing and analyzing the performance characteristics and application range of different materials, it can provide strong support for your product design and production. At the same time, it is recommended to conduct sufficient testing and verification in actual applications to ensure that the selected materials can meet the quality and performance requirements of the product.