Precision Mechanical Parts

Chaoyue Machinery is your best manufacturing partner to meet your precision machining needs. Use high-precision, high-quality processing machines to manufacture a variety of complex parts. Short lead time and guaranteed quality, please contact us for a free quote.

Introduction to Precision Mechanical Parts

Precision Mechanical Parts refer to those that, in the machining process, through high-precision processing techniques and equipment, make the parameters such as size, shape, and surface roughness of parts reach relatively high precision requirements. It has the following characteristics:

High dimensional accuracy

It can control the dimensional error of parts within a very small range to meet strict assembly requirements.

Good shape accuracy

Ensure that the geometric shape of parts is highly consistent with the design requirements, such as cylindricity, flatness, etc.

Excellent surface quality

The surface roughness of parts is low, smooth and flat, which improves the wear resistance, corrosion resistance and sealing performance of parts.

Application fields

Parts such as aircraft engine components and satellite structural parts have extremely high precision requirements and need finishing.

Key components of engines, transmission gears, etc. require high-precision processing to ensure performance and reliability.

Such as watch movements, optical instrument components, etc., have strict requirements on the precision and quality of parts.

Precision part processing is a process that uses advanced processing technologies and equipment to achieve high-precision and high-quality processing of parts.

Using computer numerical control technology to accurately control the movement trajectory and processing parameters of machine tools to achieve high-precision processing.

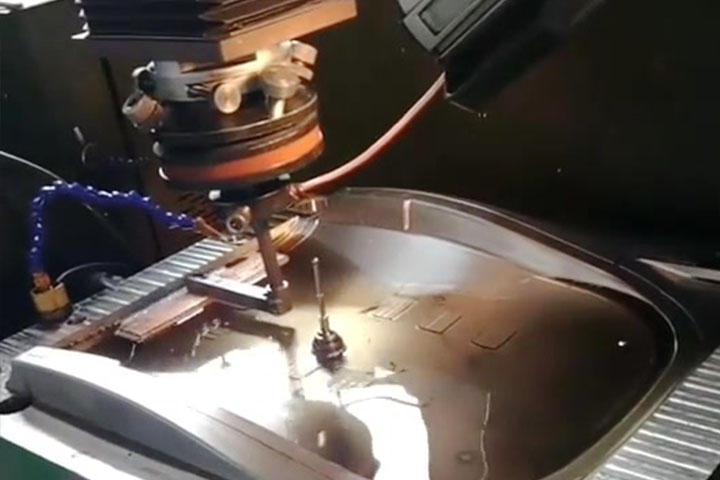

Suitable for processing parts with high hardness and complex shapes. Material is removed by discharge corrosion between the electrode and the workpiece.

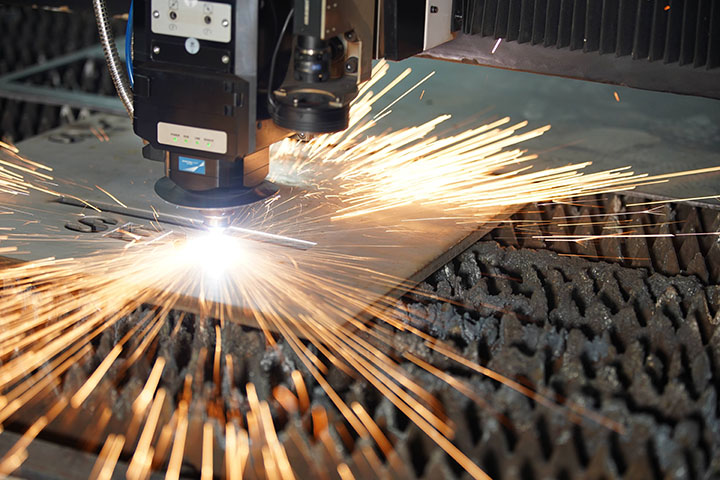

Using high-energy laser beams to cut, weld, drill and other processes on materials, with characteristics of high precision and high speed.

Strict detection means: Adopting precision measuring equipment such as coordinate measuring machines and optical microscopes to detect the size, shape and surface quality of parts.

Process control: During the processing process, monitor processing parameters such as cutting force and temperature in real time, and adjust the processing technology in time to ensure part quality.

Intelligent processing: With the development of technologies such as artificial intelligence and big data, precision part processing will develop in the direction of intelligence, realizing automation, optimization and predictive maintenance of the processing process.

Green processing: Pay attention to environmental protection and sustainable development, adopt green processing technologies to reduce energy consumption and environmental pollution.