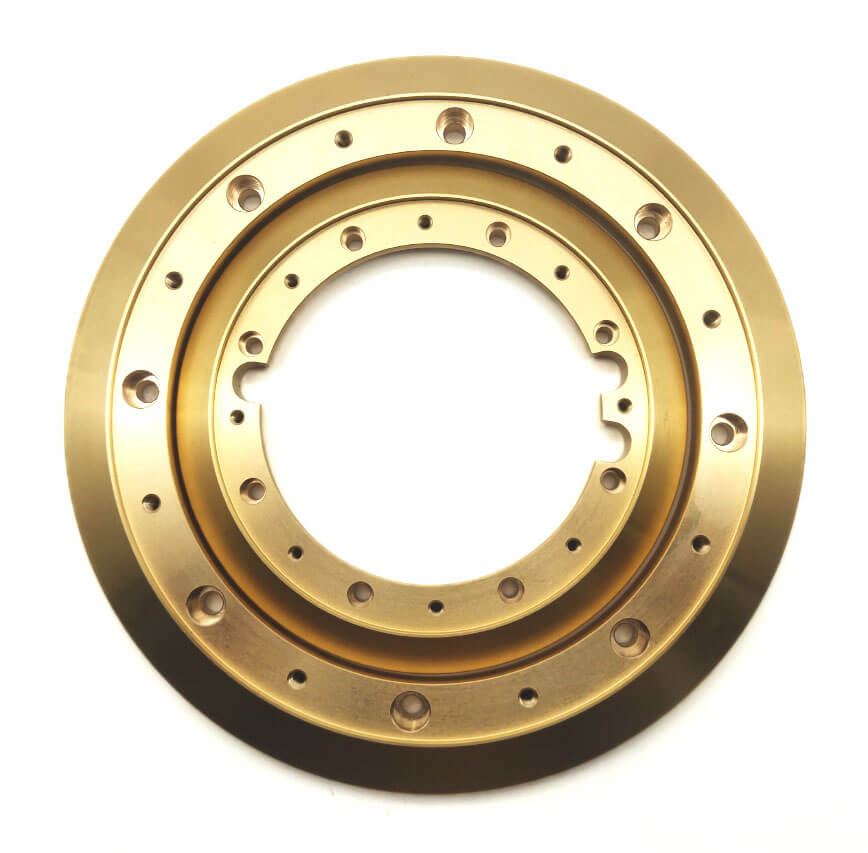

Brass Precision Parts

Brass is an alloy material with copper as the main component. The copper content in brass is between 60% and 90%, and the remaining components include various metal elements such as zinc, lead and tin. Chaoyue Machinery has more than ten years of experience in brass processing. We use advanced equipment such as CNC machine tools, high-precision turning and milling compound power turrets to ensure the accuracy and efficiency of product processing. We can not only customize and process various mechanical parts, terminal blocks, etc., but also customize various brass alloy (aluminum brass, manganese brass, tin brass and other alloys) components. It is used in high-end fields such as automation equipment, automobile manufacturing, aerospace, etc.

Brass Precision Parts And Components Applications

Brass has advantages such as good corrosion resistance, plasticity, stability, conductivity, etc. Whether it is precision parts or components of complex shapes, brass’ superior processing performance can achieve them.

We use advanced 5-axis machining equipment to provide precision brass parts for many fields. The accessories we produce include Pipe and flare fittings,Bearings,Gears,Handles,Valves,Bushings,Nuts and bolts.

Precision brass parts processing process

1

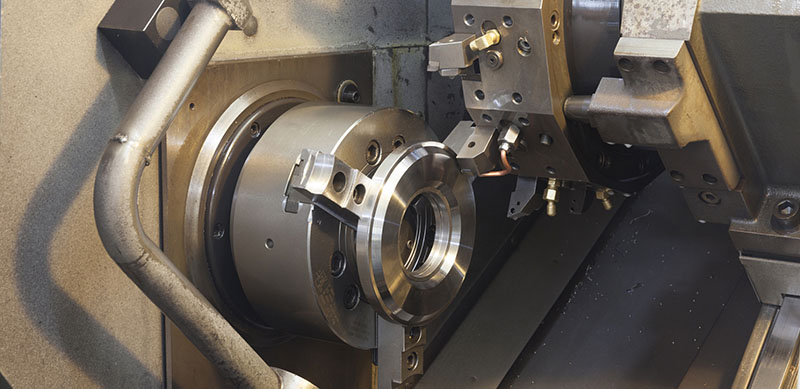

Rough machining

We use turning, milling and planing to remove excess blank material and initially form the shape and size of the parts. During the rough machining process, we fully consider the processing characteristics of brass materials and tool wear, and reasonably select cutting parameters and tool materials to improve processing efficiency and reduce costs.

2

Semi-finishing

The semi-finishing methods we commonly use include drilling, reaming, boring and tapping, etc., to further process the surface of the parts in preparation for finishing. During the semi-finishing process, we will control the machining allowance and surface quality to ensure the smooth progress of finishing.

3

Finishing

Our commonly used finishing methods include grinding, lapping and polishing to complete the final shape and size of the parts. We will consider the hardness and heat treatment state of the brass material, and reasonably select cutting parameters and tool materials to ensure the surface smoothness and precision of the parts.

4

Heat treatment

Our commonly used heat treatment methods include annealing, quenching and tempering, which are important links in the processing of brass shaft parts to adjust the mechanical properties and hardness of the material. During the heat treatment process, we strictly control the heating temperature and cooling speed to avoid problems such as material deformation and cracking.

5

Surface treatment

Our commonly used surface treatment methods include chrome plating, spraying and anodizing, etc., which are used to improve the corrosion resistance and aesthetics of brass parts. During the surface treatment process, we fully consider the characteristics and technical requirements of brass materials, and select appropriate treatment methods and process parameters to ensure surface quality and performance.

Commonly used copper alloy materials

Brass is mainly composed of copper and zinc. Different types of brass alloys can be made by changing the ratio of copper and zinc and adding other elements such as lead, tin and silicon. We provide some common copper alloy materials to help you design the right CNC machining solution.

Brass 360 (C36000)

Free-Machining Brass

Zinc (about 35%), lead and iron (about 3%) and the remaining copper make up the composition of C 360-brass. It is a highly machinable material and is widely used in gears, fittings, valves, precision parts. However, lead may cause harm to the human body if ingested, limiting its use in certain areas, such as drinking water contact applications.

Brass 260 (C26000)

Cartridge Brass

The zinc-copper formula contains small amounts of lead and iron, with zinc containing about 20% lead and 1% iron. It has good thermal conductivity, corrosion resistance and tensile strength, can be easily formed or made into various shapes, and is used in ammunition casings, pipe fittings, and electrical components.

Brass 272 (C27200)

Yellow Brass

C27200 brass has a copper content of 62-65%, a lead content of 0.07%, an iron content of 0.07%, and the balance is zinc. With its good formability, machinability, and corrosion resistance, it is used in heat exchangers, fasteners, electrical components, musical instruments, decorative hardware, and plumbing equipment.

Brass 385 (C38500)

Architectural Brass

The chemical composition includes elements such as copper (57%), zinc (40%), and lead (3%). It has good corrosion resistance, machinability, and hot workability. It is mainly used as building profiles, door and window frames, hinges, locks, and forged parts.

Brass 464 (C46400)

Naval Brass

It contains 59% copper, 40% zinc, and 1% tin. In the aviation and marine industries, its unique corrosion resistance is used in key parts such as small hardware, bolts, nuts, valve stems, condenser tubes, and welding rods on ships.

Brass 693 (C69300)

Silicon Brass

It is mainly composed of copper (75%), zinc (21.9%), silicon (3%), and phosphorus (0.1%). It has good mechanical properties, corrosion resistance, and casting properties. It is used to manufacture various mechanical parts, electrical components, instruments, decorations, etc. It has good electrical and thermal conductivity and is used to manufacture cables, heat exchangers, etc.

If you still don’t know which brass material is best for your CNC machining needs, Chaoyue Machinery’s professional team provides you with free brass precision parts processing solutions, please contact us for more information.

Frequently asked questions

Some Advantages of CNC Machining Brass

What is the best brass for machining?

Free-Machining Brass C36000 is one of the most commonly used copper alloys, with good wear resistance and machinability. During machining, C360 brass is not easy to deform or crack, and is very suitable for complex machining processes. In addition, C360 brass also has good corrosion resistance and is often used in the manufacture of pipe connectors, valve components, hardware accessories and locks.

Is brass suitable for machining?

Brass is highly machinable and is used in many mechanical and electronic applications. Compared with other metals, the hardness and strength of brass are not too high, but it is strong enough to withstand a certain amount of pressure. At the same time, brass also has good wear resistance, which prolongs the service life of precision parts.

Why is brass easy to machine?

The zinc in brass can make it easier to process, with better processing performance, corrosion resistance and mechanical strength, making it suitable for manufacturing parts subject to greater stress, such as bolts, nuts, mechanical parts, etc.