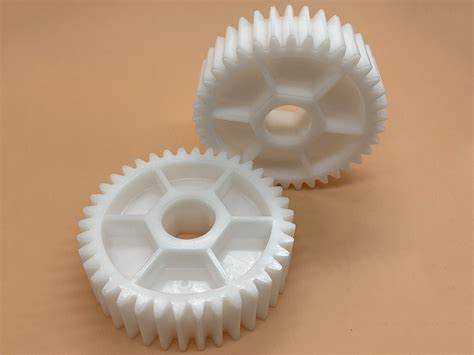

Machined Plastic Parts

20 years of injection molding experience, physical source factory, professional customization of various plastic parts processing, special-shaped plastic parts, high mold opening accuracy, neat cutting, high toughness, not easy to corrode, long service life.

Advantages of Mechanized Plastic Parts

Low raw material cost

As a common polymer material, plastic is relatively cheaper than many metal materials. In large-scale production, it can significantly reduce the cost of raw material procurement.

Low processing cost

The processing difficulty of plastic is usually lower than that of metal. The requirements for equipment and technology in the processing process are relatively simple, and the processing cycle is also relatively short, thus effectively reducing the processing cost. For example, injection molding can produce a large number of plastic parts with complex shapes in a short time, and the maintenance and operation costs of the equipment are also low.

Light weight

The density of plastic is small, and the weight of the parts made is much lower than that of metal parts of the same volume. In fields such as aerospace and automobiles, using plastic parts can significantly reduce the overall weight, improve transportation efficiency, and reduce energy consumption. For example, plastic parts are mostly used in aircraft interior parts and car bumpers.

Strong corrosion resistance

Many plastics have excellent corrosion resistance and can resist the erosion of chemical substances such as acids, alkalis, and salts. In harsh chemical environments or outdoor environments, plastic parts have a longer service life and lower maintenance costs. For example, plastic materials are often used in chemical pipelines and food packaging containers.

Good insulation performance

Plastics are generally good insulators and can effectively isolate current and prevent electrical short circuits and leakage. In the field of electronic appliances, they are widely used to manufacture insulating components such as the insulating layer of wires and cables, the casing of electronic equipment, and insulating gaskets to ensure the normal operation and safety of equipment.

Excellent wear resistance

Some plastics have excellent wear resistance. After machining, they can be made into various wear-resistant parts such as bearings, gears, and sealing rings. They can maintain good performance during long-term use, reduce wear and replacement frequency, and reduce equipment maintenance costs and downtime.

Good shock absorption

Plastics have certain elasticity and shock absorption performance, can absorb and buffer vibrations and impacts, and reduce the impact of noise and vibration on equipment and systems. They are often used in automotive suspension systems and mechanical shock-absorbing components.

Strong processability

Plastics have good plasticity and processability and can be made into various complex shapes and sizes through machining to meet different design needs. Whether it is a simple geometric shape or a complex three-dimensional structure, it can be realized through various methods such as injection molding, extrusion, and CNC machining, providing greater space for product design and innovation.

High molding precision

Modern plastic processing technologies, such as precision injection molding and CNC machining, can achieve high molding precision and manufacture parts with high dimensional accuracy and good surface quality, meeting the requirements of some application scenarios with high precision requirements, such as electronic equipment parts and medical devices.

Good recyclability

Many plastic materials can be recycled and reused, which helps reduce environmental pollution caused by waste and reduce resource waste, meeting the requirements of sustainable development. After the end of the product’s service life, plastic parts can be recycled and reprocessed into new plastic products to realize the recycling of resources.

Fast molding speed

Taking injection molding as an example, it can complete the molding process of a part in a short time, and multiple parts can be manufactured in one molding, with high production efficiency, suitable for mass production, and can meet the needs of large-scale production and effectively improve production efficiency.

Easy to automate production

The plastic processing process is relatively easy to achieve automatic control. For example, injection molding machines can be combined with automated production lines to realize fully automated production from raw material transportation, molding to part removal, reducing manual intervention, improving production efficiency and product quality stability, and reducing production costs.

Application Fields of Mechanized Plastic Parts

Automotive industry

Plastic parts are usually used in automotive interior parts such as dashboards, seats, door panels, and center consoles. They not only have light weight and low cost but also can achieve good comfort and aesthetics. For exterior parts such as bumpers, radiator grilles, and body side skirts, using plastic materials can reduce the weight of the vehicle body while ensuring strength and improve fuel economy. In addition, some parts in the engine compartment of automobiles, such as intake pipes, fuel pipes, and wire harness fasteners, also use plastic parts, taking advantage of their corrosion resistance, insulation, and good formability.

Electronic and electrical industry

The casings of consumer electronic products such as mobile phones, computers, and televisions usually use plastic materials. Through machining, various exquisite appearance designs and complex structures can be realized, and at the same time, functional requirements such as electromagnetic shielding and heat dissipation can also be met. In addition, various parts inside electronic equipment, such as circuit board brackets, insulating gaskets, connectors, and switch buttons, also use a large number of plastic parts to ensure the normal operation and safety of the equipment.

Medical device field

Some casings, handles, trays and other components in medical devices are often made of plastic materials, which have the advantages of light weight, easy cleaning and disinfection, and good biocompatibility. Some disposable medical supplies, such as syringes, infusion tubes, and blood collection tubes, are also made of plastic. While ensuring safety in use, the cost is reduced. In addition, in some high-end medical devices, such as medical imaging equipment and minimally invasive surgical instruments, high-performance plastic parts are also used to meet the requirements of high precision and high reliability.

Machinery manufacturing industry

In machinery manufacturing, plastic parts can be used to manufacture various transmission components such as gears, chains, and pulleys. Their good wear resistance and self-lubricating properties can reduce energy loss and wear during the transmission process. They can also be used to manufacture mechanical structural parts such as workbenches, sliders, and guide rails. While ensuring strength and precision, they can reduce the weight of equipment. In addition, some sealing parts, gaskets, and shock-absorbing pads are also made of plastic and are used to prevent leakage, buffer vibration and reduce noise.

Packaging industry

Plastic packaging has the advantages of light weight, low cost, high transparency, moisture resistance, and corrosion resistance. Therefore, it has been widely used in the packaging of food, beverages, medicines, daily necessities and other products, such as plastic bottles, plastic cans, plastic films, plastic bags, etc. Most of these plastic packaging products are made by machining processes such as injection molding and blow molding.

Construction industry

Plastic pipes are one of the commonly used materials in construction, such as water supply pipes, drainage pipes, gas pipes, etc., which have the advantages of corrosion resistance, wear resistance, not easy to scale, and convenient installation. In addition, plastic doors and windows, plastic floors, plastic wall panels, etc. have also been more and more widely used in construction. They are not only beautiful and durable but also have good thermal insulation and sound insulation properties.

Toy industry

Plastic toys are deeply loved by children because of their bright colors, diverse shapes, and safety and environmental protection. Through machining, toys of various shapes and functions can be manufactured, such as plastic building blocks, plastic dolls, plastic toy cars, etc., to meet the needs of children of different ages.

Aerospace field

In the aerospace field, the application of plastic parts is also becoming more and more extensive. For example, plastic materials are used in aircraft interior parts, aviation seats, instrument panels, wires and cables, etc., which can effectively reduce the weight of the aircraft, improve fuel efficiency and reduce operating costs. In addition, some high-performance plastic composite materials are also used to manufacture aircraft structural parts, wings, fuselages, etc., to meet the performance requirements of high strength, high heat resistance, and high weather resistance.